The principle of table drills in daily operations

DATE: 2024-04-28

Hits: 745

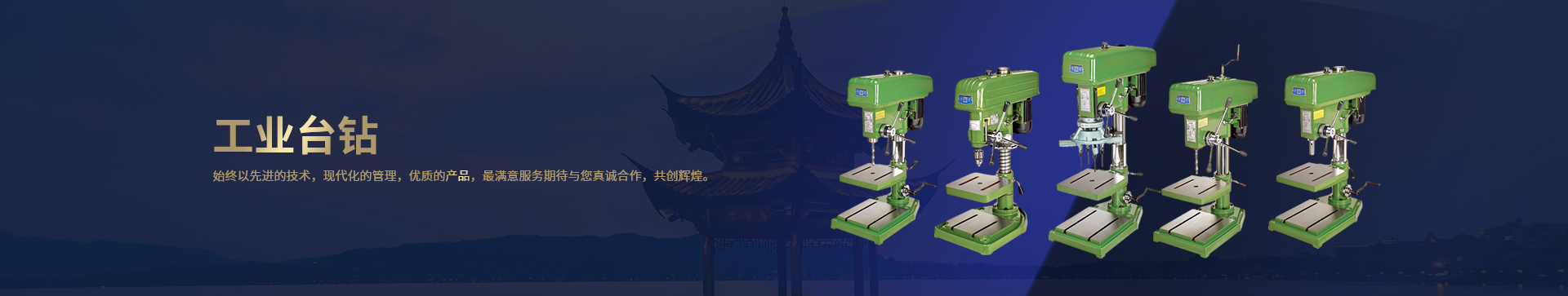

Platform drills are convenient and flexible to use, with high production efficiency, suitable for various parts processing, assembly, and repair work. Small hole machining machines typically installed on specialized workbenches are typically below 13 millimeters and up to a maximum of 16 millimeters. Its speed change is generally achieved by changing the position of the triangular belt on the tower pulley, and the spindle feed is manually operated.

Today, we will mainly teach you the role of a bench drill in daily work and how it works:

The function of a table drill is the same as that of a hand electric drill, which can drill holes and be fixed on the tool table, making it more firm and stable, with higher accuracy and precision. It belongs to the category of machining machinery.

A table drill is powered by an electric motor, which is transmitted to the spindle through a tower belt pulley through variable speed. The outermost part of the spindle is a sleeve that does not rotate but only moves in a straight line. It has a rack structure on top, which is combined with gears to form a longitudinal feed mechanism. The spindle is installed in this sleeve, and the spindle can rotate freely inside the sleeve. However, the up and down movement of the sleeve will drive the spindle to move up and down. The innermost part is a relatively long sliding spline, and the spindle can move up and down freely on the spline, but it needs to rotate together with the spline. A hollow tower belt pulley is fixed on the upper end of the spline, and the power of the drill bit is transmitted to the spindle through the spline.